BOM Rule

BOM Rules in ianaiERP allow you to create dynamic Bills of Materials with conditional logic and automated component selection. This powerful feature enables flexible manufacturing configurations that adjust based on the attributes of your built items.

Overview

BOM Rules automate the process of determining which components are included in a BOM.

Rules can filter items based on various criteria and calculate quantities dynamically.

This feature is especially useful for configurable products or those with multiple variations.

Rule Expression Format

BOM Rules use a structured format with conditions, dynamic item filters, and quantity calculations.

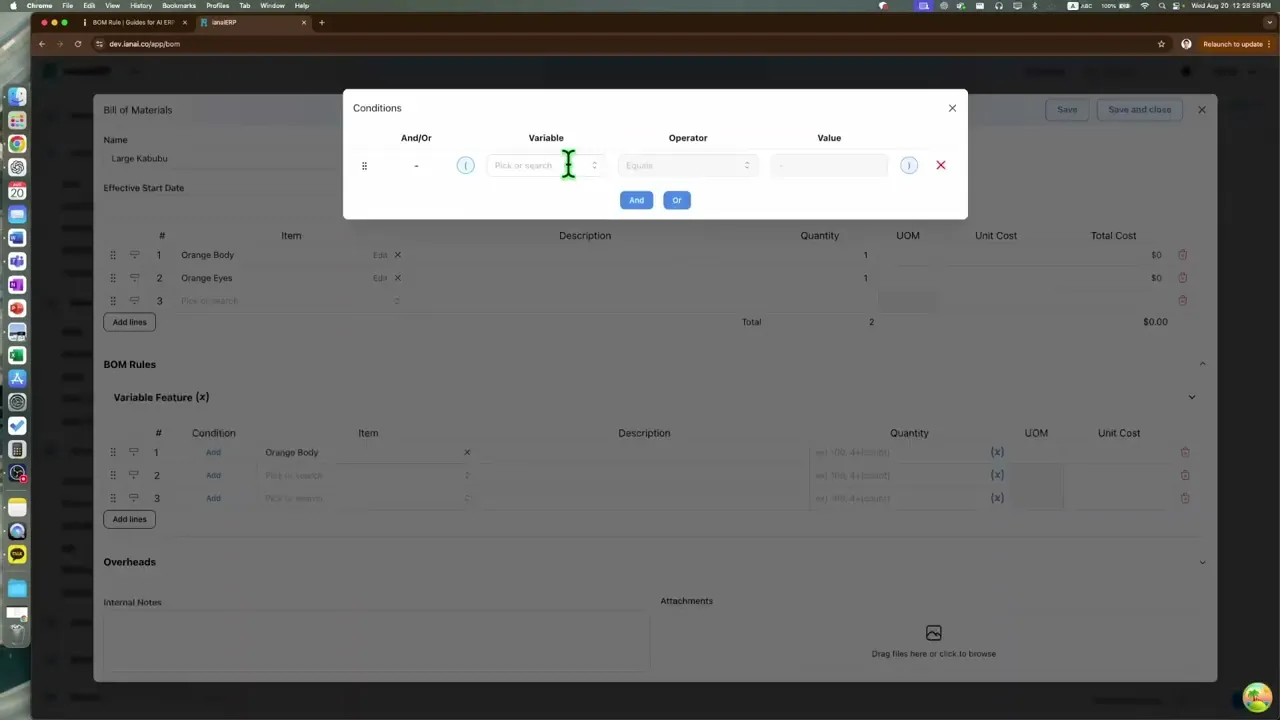

Conditions Format

Conditions use the following syntax:

Plain text

Where:

labelis the attribute or option of the built itemoperatoris the comparison methodvalueis the criteria for comparison;separates each condition

Special characters | and ; are reserved for syntax and cannot be used as key values.

Example:

Plain text

Supported Operators

Operator | Description | Format | Applicable Value Types |

|---|---|---|---|

Equal | Exact match |

| text, number, date, boolean, list |

NotEqual | Not matching |

| text, number, date, boolean, list |

Blank | Is empty |

| text, number, date, list |

NotBlank | Is not empty |

| text, number, date, list |

GreaterThan | Greater than |

| number, date |

GreaterThanEqual | Greater than or equal |

| number, date |

LessThan | Less than |

| number, date |

LessThanEqual | Less than or equal |

| number, date |

Contains | Contains text |

| text |

NotContains | Doesn't contain text |

| text |

StartsWith | Starts with text |

| text |

NotStartsWith | Doesn't start with text |

| text |

EndsWith | Ends with text |

| text |

NotEndsWith | Doesn't end with text |

| text |

In | Value in list |

| list |

NotIn | Value not in list |

| list |

Dynamic Item Filters

Dynamic item filters let you automatically select BOM components based on criteria:

Example:

Plain text

Where:

filter_by_*functions create filter conditionsorder()functions determine sorting orderVariables in curly braces

{xxx}reference the built item's attributes or options

Example:

Plain text

Quantity Calculations

Quantity calculations allow you to dynamically adjust the quantity of BOM components:

Dynamic Quantity Calculation

Quantities can be expressed as static values or dynamic calculations:

Static:

100Simple addition:

100+{quantity}Formula with multiple variables:

{width}*{height}/100

Where variables in curly braces

{xxx}reference the built item's attributes or options.

If you want to use component's attribute use the prefix 'mattr_'. e.g.){mattr_width}

Available functions: ROUND()

e.g.) ROUND({width}) or ROUND({width},2). The number after comma is precision.

Creating BOM Rules

To create a BOM Rule:

Navigate to Manufacturing > BOM in the main menu.

Find and select BOM relates to the assembly item for which you want to create a rule-based BOM.

In the BOM detail view, Open the BOM Rules tab.

Create rule-based components.

Add your rule expressions following the formats described above.

Best Practices

Test your BOM rules with various configurations to ensure they produce the expected results.

Use clear and meaningful attribute names in your rules for better readability.

Start with simple rules and gradually add complexity as needed.

Document your rule logic separately for future reference.

Regularly review and update BOM rules when product specifications change.

Related Features

For more detailed information on advanced BOM rule techniques and optimization, please refer to the specific sections in this documentation.

Join our Community Forum

Any other questions? Get in touch