Routing

Routing in ianaiERP defines the sequence of operations and resources required to manufacture a product. It's a critical component of work orders that outlines the production process flow from start to finish.

Overview

Routing specifies the step-by-step operations needed to transform raw materials into finished goods.

Each operation in a routing includes details about work centers, labor, setup time, and run time.

Properly configured routings help optimize production scheduling, resource allocation, and cost calculation.

Where to Access

Users (admin / common) can access item via Manufacturing column (Manufacturing: Routing)

Click Add New to initiate adding routings onto the ianaiERP system

Key Attributes

Header

Name — Internal name of the routing variant (e.g., “Std – 500ml”).

Item — Finished good this routing applies to.

Default (toggle) — If on, this routing auto-selects for the item on new Work Orders.

Effective Start / End Date — Validity window; scheduler should not use the routing outside these dates.

Default Cycle Time — Target cycle time per unit; used as a planning reference for capacity/throughput.

Operation Lines

# (Sequence) — Execution order of steps (drag to reorder; typical values 10/20/30…).

Operation Name — Step label shown to the shop floor (e.g., Cut, Drill, Pack).

Setup Time (m) — One-time preparation time per batch/run at this step.

Run Time (m) / unit — Processing time per unit at this step (drives capacity/cost).

Work Center — Machine/cell/resource that performs the operation (rates feed costing and scheduling).

Print Template — Traveler/label/SOP to print for this step, if required.

Routing Rules (conditional operations)

Variable Feature (x) — Ruleset that inserts/overrides operations based on item options/attributes.

Condition — Criteria that must be met (e.g., option = “Stainless”) for the rule to apply.

Operation fields (Name, Setup, Run, Work Center) — Values to use when the condition is true.

Ordering — Sequence number to place the conditional operation in the flow.

Print Template — Document override for the conditional step.

Notes & Files

Notes — Free-form instructions or cautions for planners/operators.

Attachments — Upload SOPs, drawings, checklists, or QC forms used during the routing.

Key Functions

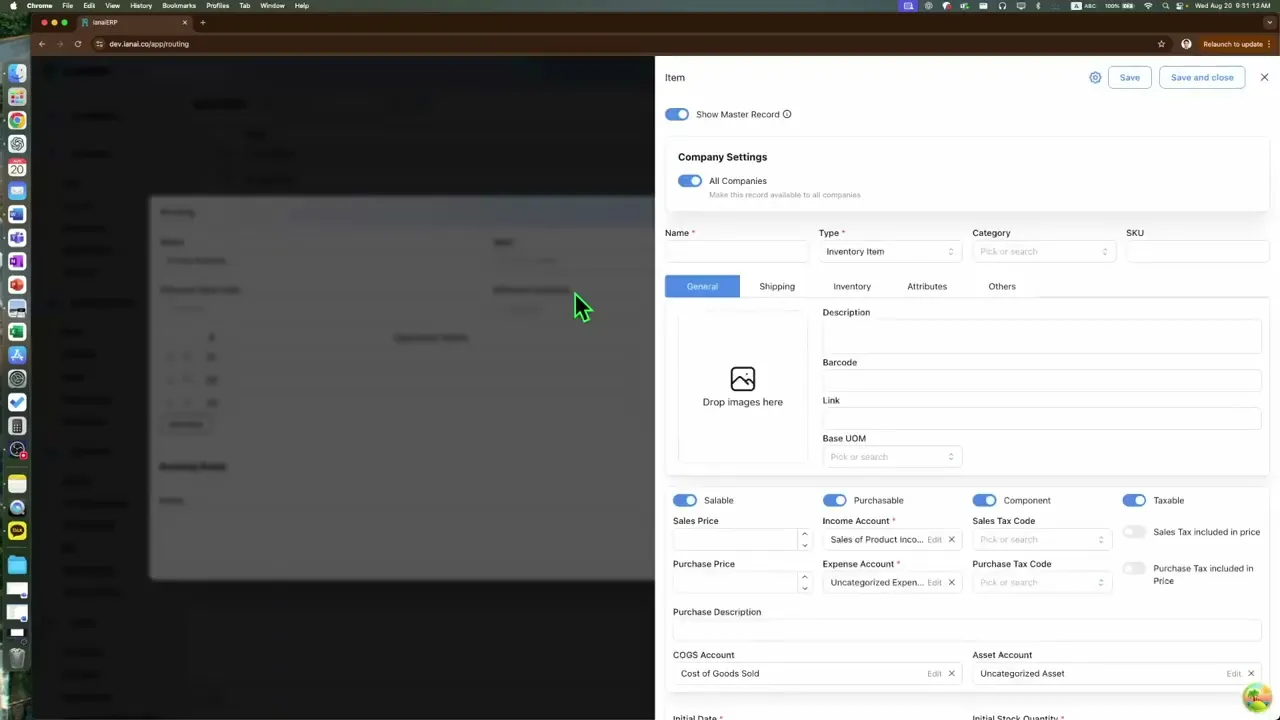

Create a routing

Manufacturing → Routings → New Routing

Enter name and description

Add operations to define the process flow

Add operations

Add Operation → fill Name, Work Center, Setup Time, Run Time

Set Sequence Number; add special instructions/requirements

Assign a routing to a work order

Manufacturing → Work Orders → New/Select → choose Routing

Operations from the routing are auto-populated; adjust as needed

Create routing rules

Manufacturing → Routing Rules → set conditions (variable/operator/value) → choose routing if met → (optionally) use variables for setup/run time per unit → Save

Related Features

For more detailed information on advanced routing techniques and optimization, please refer to the specific sections in this documentation.

Join our Community Forum

Any other questions? Get in touch