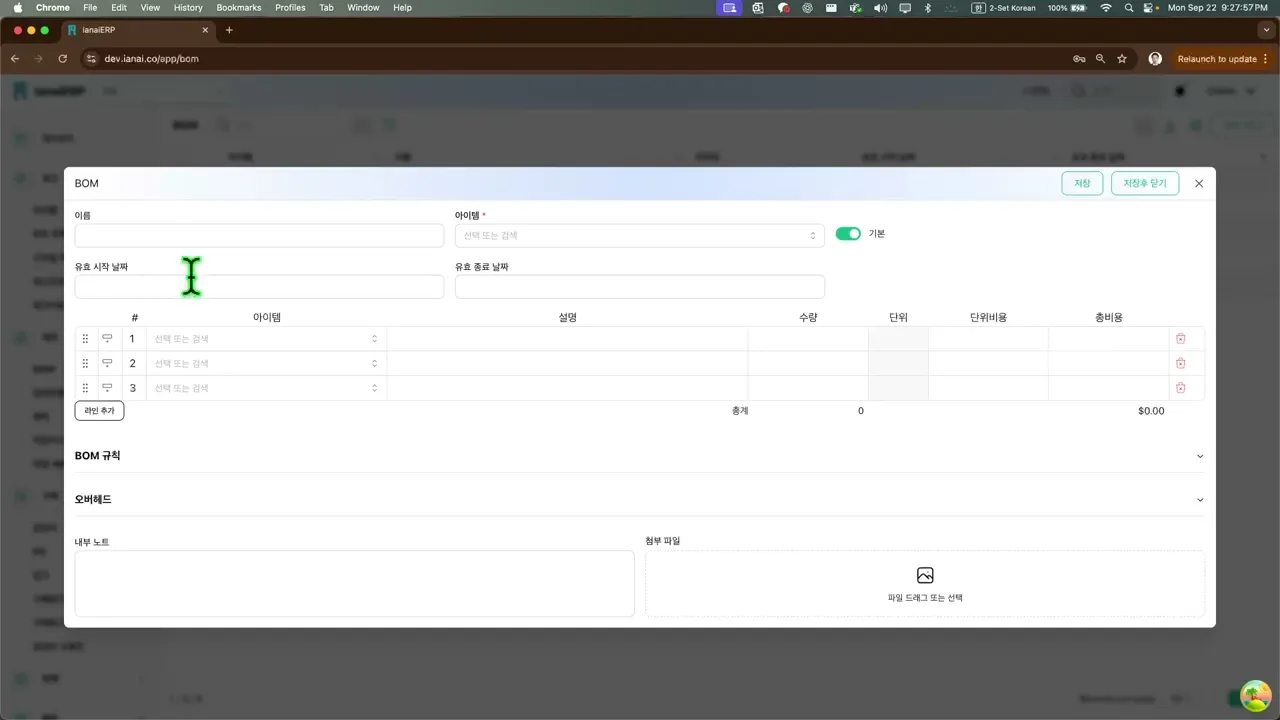

BOM

자재명세서(BOM)는 완제품 또는 조립품을 제조하는 데 필요한 구성품, 수량, 비용을 나열한 목록입니다. BOM은 제품의 구조/구성을 정의하고, 완제품 1단위당 정확한 소요 수량을 명시하며, 정확한 원가 계산, 재고 관리, 생산 계획을 지원합니다.

개요

BOM(자재명세서)은 조립 제품의 구조와 구성 요소를 정의합니다.

완제품 1개를 만들기 위해 필요한 각 구성품의 정확한 수량을 지정합니다.

정확한 원가 계산, 재고 관리, 생산 계획에 도움을 줍니다.

접근 경로

메뉴: Manufacturing(제조) > BOM 에서 확인/생성할 수 있습니다.

핵심 속성

헤더

이름: 이 BOM의 내부 이름.

아이템: 이 BOM이 생산하는 완제품/조립품 아이템.

기본: 선택한 아이템의 기본 BOM으로 지정.

유효 시작 날짜 / 유효 종료 날짜: BOM 사용 유효 기간(선택).

구성품 라인(행 단위)

아이템: 구성품 코드 또는 명칭.

설명: 라인 설명(선택).

수량: 완제품 1개 생산에 필요한 수량.

단위: 해당 수량의 단위.

단위 비용: 구성품 단가.

총 비용: 자동 계산(Quantity × Unit Cost).

라인 추가: 행 추가/삭제, 순서 변경.

BOM 규칙(선택)

조건: 해당 구성품을 포함할 조건.

아이템: 조건 충족 시 포함될 구성품.

설명: 메모(선택).

수량: 식 지원(예: 4+{count}).

단위/단위비용: 위와 동일한 의미.

※ 규칙 문법과 고급 사용법은 매뉴얼의 BOM Rules 절을 참고하세요.

간접비(선택)

오버헤드: 인건비/수수료 등 비자재 비용 라인.

설명 / 수량 / 단위비용 / 총비용: 비자재 비용 수집 항목.

메모 & 파일

내부 노트: 작업 지시/주의사항 등 내부 메모.

첨부파일: 사양서, 도면 등 관련 문서 드래그앤드롭 첨부.

핵심 기능

BOM 생성: 제조 > BOM > 새로 추가 → 이름 입력 → 아이템 선택 → (선택) 유효기간 설정 → (필요 시) 기본 지정 → 구성품 라인추가.

오버헤드 추가: 인건비/수수료 등은 오버헤드 라인에 입력하여 완전한 원가를 반영.

BOM 규칙 사용(선택): 조건부로 구성품을 포함할 조건행을 추가하고, 수량은 수식 사용 가능.

정확성 유지(권장 사항)

모든 구성품을 정확히 식별하고 수량을 정확히 입력하세요.

공정 변화나 단가 변동 시 BOM을 정기적으로 검토/갱신하세요.

BOM 전반에 기본 단위를 일관되게 사용하세요.

인건비·간접비를 포함해 모든 관련 비용을 반영하세요.

복잡한 제품은 다단계 BOM를 고려하세요.

연관 기능

Join our Community Forum

Any other questions? Get in touch