작업 계획

ianaiERP의 작업계획은 여러 작업지시를 일괄 생성·추적하여 대규모 생산을 관리하는 강력한 도구입니다. 특히 다수의 판매주문을 대상으로 생산할 때 중앙집중형 생산계획 수립과 관리를 가능하게 합니다.

개요

작업계획은 여러 판매주문을 하나의 생산 일정으로 묶어 관리합니다. 생산관리자는 부서·사업장 전반의 작업을 정리하고, 한 개의 작업계획에서 여러 작업지시를 생성·추적할 수 있습니다. 다수 주문을 동시에 처리할 때 생산 계획을 간소화합니다.

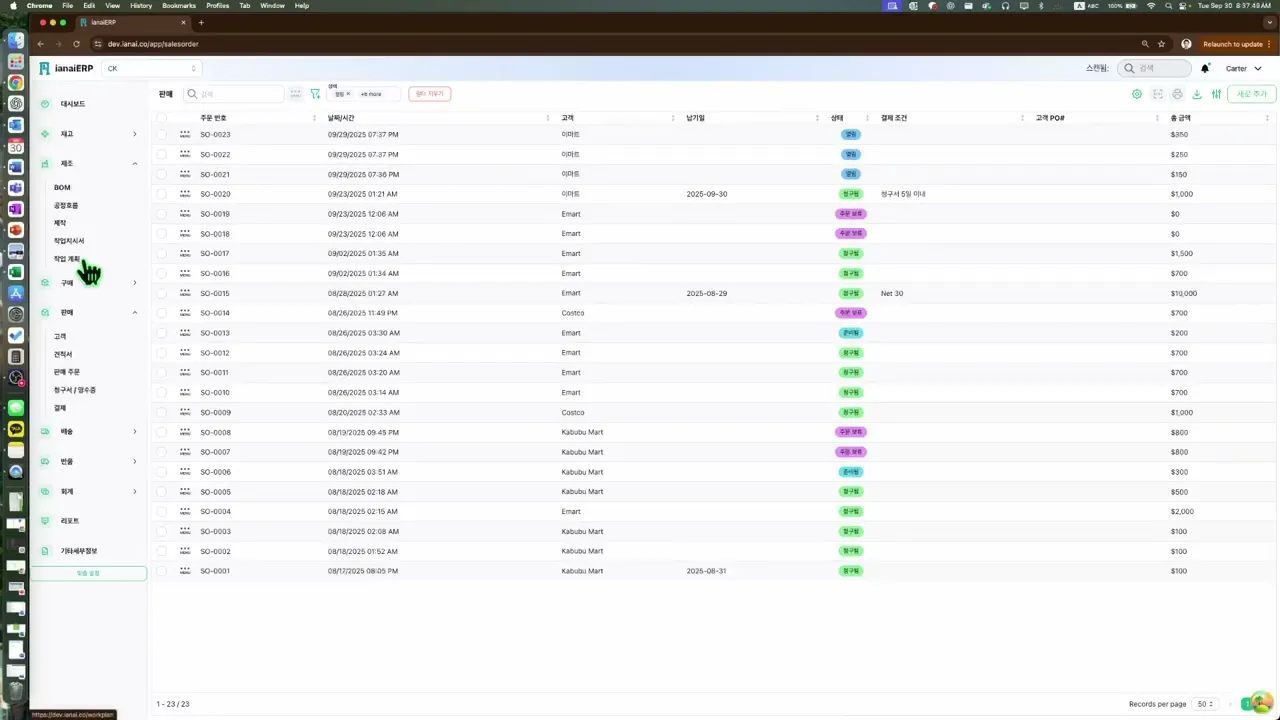

접근 경로

좌측 메뉴 → 제조 → 작업계획

주요 항목

작업계획 목록(컬럼)

작업계획 번호: 자동/수동 부여 식별자

일시: 생성 시각

상태: 대기 / 발행 / 진행중 / 완료

내부 메모: 계획 수립 메모

부서: 담당 부서

위치: 주 생산 사업장/물류센터

프로젝트 코드: 프로젝트 단위 추적용(선택)

작업계획 상세(헤더)

일시: 계획 생성 시간(수정 가능)

작업계획 번호: 자동 생성(권한 시 수정 가능)

부서: 책임 부서

위치: 작업지시 기본 사업장

프로젝트 코드: 원가/리포팅 참조(선택)

판매주문 추가: 한 개 이상 연결

라인 테이블(행별)

순번: 드래그로 재정렬

판매주문: 생산 대상 주문

아이템: 생산할 완제품

설명: 품목 설명(읽기 전용)

현재고: 완제품 재고

수량: 생산 수량

마감일: 목표 완료/출고일

작업지시: 생성 후 연결 번호 표시

위치: 해당 라인의 실제 생산 사업장(헤더와 다를 수 있음)

바닥글

메모: 계획/현장 지시 사항

첨부파일: 도면, 사양, 요구 문서

핵심 기능

새 작업계획 생성

제조 → 작업계획 → 새로 만들기

일시, 부서, 위치, (선택) 프로젝트 코드를 입력

‘판매주문 추가’로 한 개 이상 선택 후 추가

각 라인에 아이템, 수량, 마감일, 위치 확인

저장하면 상태는 ‘대기’

작업지시 생성

라인별 ‘작업지시’ 컬럼에서 생성(행당 1건)

생성 후 작업지시 번호가 표시됨

모든 라인 작업지시 생성 후 계획 상태를 ‘발행’으로 전환

진행 추적

발행: 작업지시 생성 완료, 착수 대기

진행중: 연결된 작업지시 중 하나 이상 착수

완료: 연결된 모든 작업지시 완료

목록에서 상태/부서/위치 필터로 부하 모니터링

계획 종료

모든 연결 작업지시가 ‘완료’가 되면 저장 시 계획 상태도 ‘완료’로 갱신(또는 ‘모든 작업지시 완료’ 버튼 표시 시 클릭)

상태

대기: 초안, 자유롭게 편집 가능, 생산 미배포

발행: 현장 배포, 자재/공정 실행 준비 완료

진행중: 한 개 이상 공정 착수, 시간·소모 기록 가능

취소: 더 이상 진행 없음, 추가 반영 차단

완료: 모든 공정 종료, 자재 소모·완제품 반영 완료

우수적용사례

유사 품목/공유 설비를 한 계획에 묶어 교체시간 최소화

현재고를 확인해 과잉생산 방지

마감일을 판매주문 출고일과 정렬

공통 사양은 메모/첨부에 기록해 현장 혼선을 방지

프로젝트 코드를 활용해 계획 간 원가·처리량을 비교

연관 기능

Join our Community Forum

Any other questions? Get in touch