입고

입고 처리는 재고 품목이 귀사의 사업장 또는 다른 위치에 도착한 사실을 기록하는 절차입니다. 이 중요한 단계는 재고 기록을 정확하고 최신 상태로 유지하도록 보장합니다.

개요

입고 처리는 ‘입고 전표’를 생성하여 수행합니다.

입고 전표는 단독으로 만들 수도 있고, 기존 PO에 연결할 수도 있습니다.

PO에 포함된 품목은 부분 입고(일부 수량만 입고)를 지원합니다.

수입부대비용(운임, 관세 등)을 포함해 재고의 실질 원가를 계산할 수 있습니다. (현재 미구현)

접근 경로

제조 메뉴에서 ‘입고’ 화면에 접근할 수 있습니다.

주요 항목(요약)

상단(헤더)

일시: 입고 시각.

PO: 기존 발주서에 연결(선택).

공급업체: 이번 입고의 거래처.

입고 번호: 시스템 자동 생성 또는 수기 입력.

위치: 입고가 이루어지는 사업장/창고.

검사 필요(표시되는 경우): 입고 후 검사가 필요한지 표시.

주소

공급업체 주소 / 배송지 주소: 거래처/위치 정보 기준 자동 채움, 문서에서 수정 가능.

품목(행 단위)

품목: 입고 대상 제품.

설명: 행 메모/세부 사항.

수량: 입고 수량(부분 입고 가능).

단위: 수량 단위.

단가 / 금액 / 세금: 해당 행의 원가와 세금.

로트/시리얼(해당 시): 로트 번호와 유효기간(로트 추적), 또는 시리얼 입력.

오버헤드

항목: 운임, 관세, 통관수수료 등.

설명: 비용 내역.

수량 / 단가 / 합계: 비용 금액.

입력된 부대비용은 입고된 품목에 배분되어 재고자산가치에 반영됩니다.

하단/기타

부서 / 프로젝트 코드: 보고용 선택 태그.

내부 메모: 내부 참고용 코멘트.

첨부파일: 패킹슬립, 선하증권, 사진 등 드래그앤드롭 첨부.

주요 기능

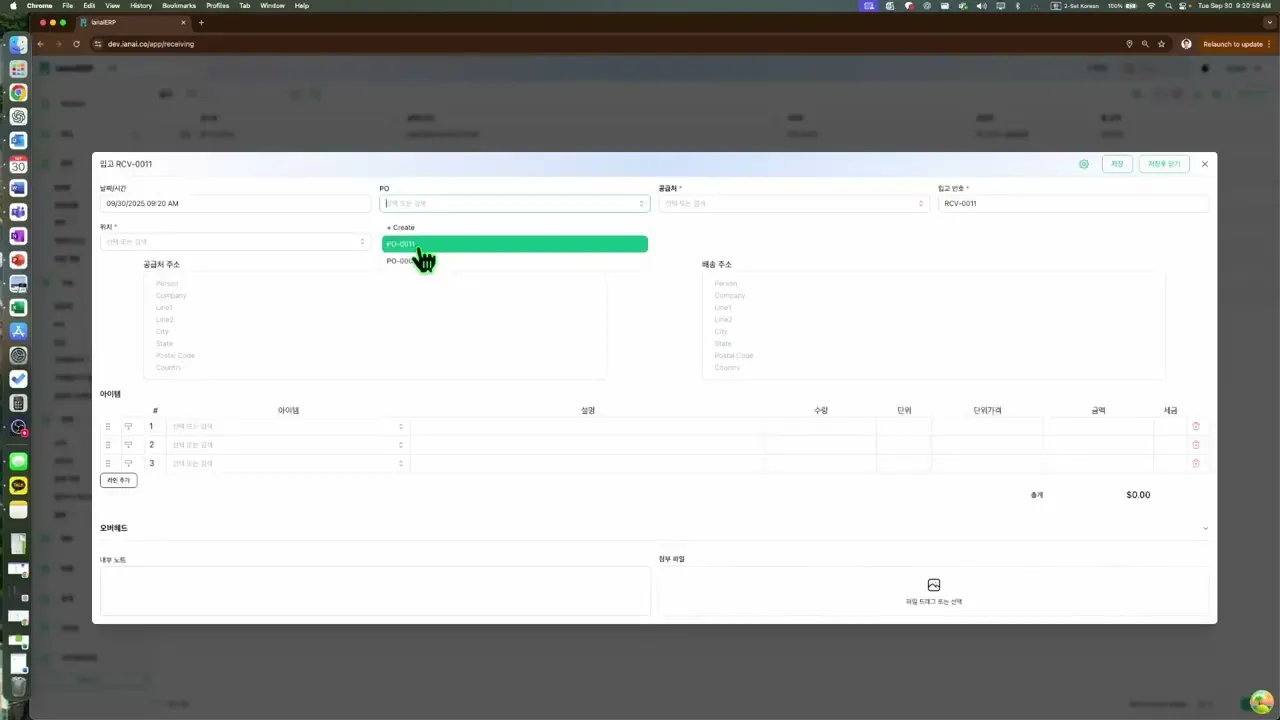

입고 전표 생성

구매 ▸ 입고 ▸ 새로 추가로 이동합니다.

(선택) PO를 선택해 미입고 행을 불러옵니다.

공급업체, 위치, 일시를 설정하고 입고 번호를 확인합니다.

품목 추가

각 행에서 품목을 선택하고 수량을 입력한 뒤 단위/단가를 확인합니다.

로트/시리얼 추적 품목은 정책에 따라 로트·유효기간 또는 시리얼을 입력합니다.

부대비용 추가(수입부대비용)

부대비용 영역에 운임/관세 등 비용 행을 추가합니다.

저장하면 비용이 품목별로 배분되어 재고가치에 반영됩니다.

저장 및 PO 반영

전표를 저장합니다.

발주서에 연결된 품목의 경우, 해당 입고 수량이 발주서에 자동 반영됩니다.

발주서는 전 수량 입고되기 전까지 열린 상태로 유지되며, 필요 시 수동 종결할 수 있습니다.

모범 사례

저장 전, 패킹슬립/발주서와 수량을 대조하여 정확히 입력합니다.

로트·유효기간을 정확히 입력해 추적성을 확보합니다.

패킹슬립과 운임/통관 관련 청구서를 첨부해 근거를 남깁니다.

부서/프로젝트 태그를 활용해 이후 보고서 정합성을 높입니다.

공급업체 청구서와 정기적으로 대사하여 입고·원가를 일치시킵니다.

관련 기능

자세한 입고/검수/원가 배분 절차는 본 문서의 관련 섹션을 참고하십시오.

Join our Community Forum

Any other questions? Get in touch