제작

ianaiERP에서 제작은 원자재 또는 구성 부품을 조립하여 완제품을 생산하는 과정을 관리하는 데 사용됩니다. 이 기능은 제조 또는 조립 공정을 수행하는 기업에 필수적입니다.

제작

개요

제작은 원자재/구성품을 소비하여 완제품(조립품)을 만들어 재고로 반영하는 단일 단계(원샷) 조립 트랜잭션입니다.

BOM(자재명세서)를 기준으로 구성품과 수량을 자동 불러오며, 필요 시 수량·대체품·로트/시리얼을 조정할 수 있습니다.

다단계 공정·WIP(재공품) 추적이 필요한 경우에는 작업지시서를 사용하고, 간단한 조립·패키징·킷팅에는 제작이 적합합니다.

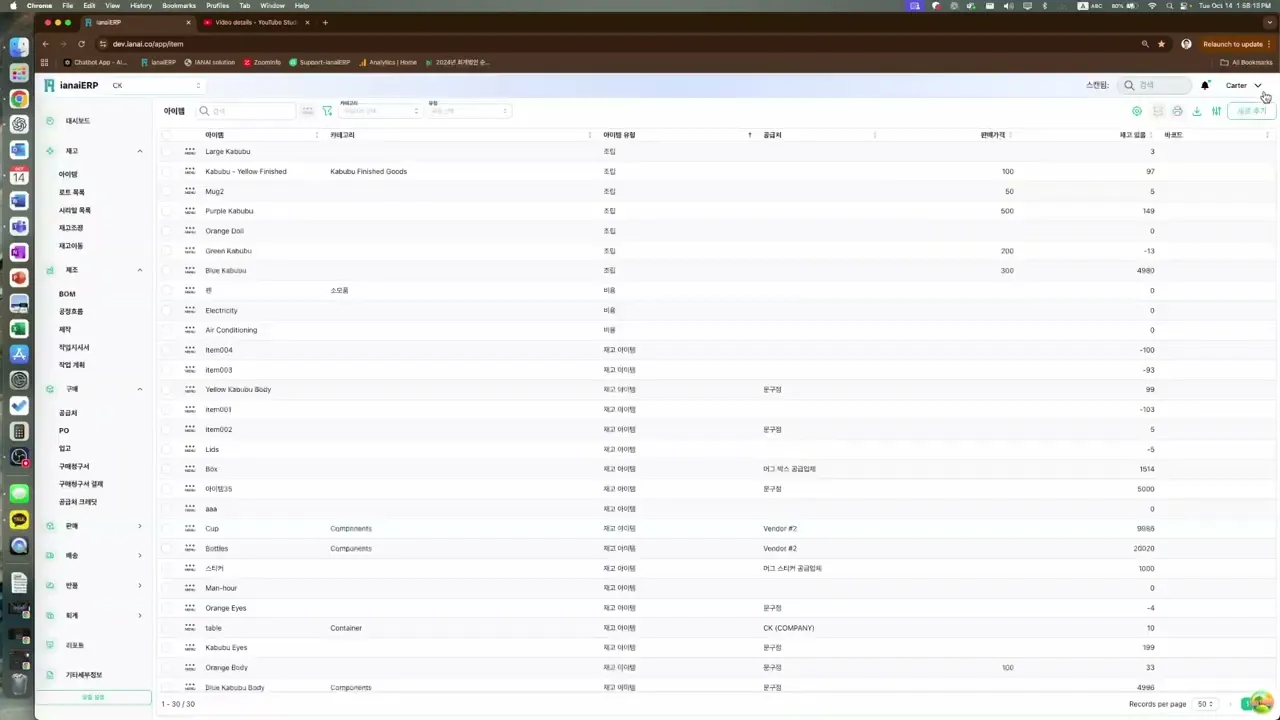

접근 경로

메인 메뉴 → 제조(Manufacturing) → 제작

아이템 상세(조립품) → 제작 생성 바로가기(있는 경우)

주요 속성

1) 헤더

회사 설정: (모든 회사/특정 회사) 가용 여부.

문서 번호/이름: 내부 식별자(자동/수동).

상태: 임시저장 → 확정.

제작 일자: 원가 반영·재고 이동 기준일.

메모/내부 메모: 작업 지시사항·특이사항.

첨부파일: 도면, 작업 사진, 검사 성적서 등.

2) 위치/빈(위치/빈 트래킹)

From 위치/빈: 구성품을 불출/소모할 창고·빈.

To 위치/빈: 완제품을 입고할 창고·빈.

로트/시리얼/빈 트래킹이 활성화된 경우 각 라인에서 선택 필수.

3) 조립품(완제품) 정보

아이템: 제작으로 생성할 조립품.

수량(UOM): 생산 수량(기준 UOM).

원가 정책: 시스템의 평가 방법에 따라 조립 원가가 자동 산출(구성품 원가+제조경비).

4) 구성품 라인

아이템/설명: BOM 기준 자동 로드, 수동 추가 가능.

필요 수량(표준): BOM 기준 단위 수량 × 빌드 수량.

불출 수량(실제): 실제 소모 수량(필요 시 수정/대체 허용).

UOM: 구성품 단위.

로트/시리얼: 추적 품목은 선택 필수(모달에서 검색/자동선택 가능).

빈: 빈 트래킹 시 From Bin 지정.

대체품: 승인된 대체자재로 교체 가능(정책에 따름).

5) 오버헤드/제조경비(선택)

항목/설명/수량/단가/금액: 노무비, 가공비, 외주비 등 별도 계상. 조립 원가에 합산.

6) 원가 결과

구성품 소모 원가 합계 + 오버헤드 = 조립품 투입 원가.

확정 시 조립품 자산 계정 증가, 구성품 재고 감소가 전표에 반영.

주요 기능

A. 새 제작 생성

제조 → 제작 → 새로 추가.

조립품, 수량, 제작 일자, From/To 위치(및 빈)를 지정.

BOM 불러오기를 통해 구성품 라인을 자동 채움.

각 라인에서 필요 시 대체자재, 불출 수량, 로트/시리얼, 빈을 지정.

저장 → 확정. 확정 시 재고·원가가 반영되고 히스토리가 기록됩니다.

B. 로트/시리얼 선택(트래킹 품목)

라인 우측 시리얼 버튼 → 모달에서 검색/필터/일괄선택.

수량 = 선택한 로트/시리얼 개수와 정확히 일치해야 저장/확정 가능.

자동 시리얼 사용 품목은 수량 입력 시 자동 생성 지원(설정에 따름).

C. 부분 제작/나눔 제작

동일 조립품에 대해 여러 건으로 나누어 제작하여 단계적 입고 가능(예: 100개 목표를 40/60으로 분할).

D. 역조립(취소/반전)

잘못 확정한 건은 반전 기능으로 되돌릴 수 있음(권한/정책에 따름).

조립품 재고를 감소시키고 원자재를 재입고합니다(가용 수량 조건 필요).

E. 대체자재 사용

구성품이 부족하거나 변경된 경우 대체품으로 교체하여 불출 가능.

원가/재고는 실제 소모된 항목 기준으로 반영됩니다.

F. 멀티로케이션·빈 이동

From/To 위치(및 빈)를 각각 지정하여 소모 위치 ≠ 입고 위치 처리 가능(예: 라인창고 소모 → 완제품창고 입고).

G. 회계 영향(요약)

확정 시 전형적으로 다음이 반영됩니다(계정은 아이템 설정에 따름):

구성품: 재고자산 감소(크레딧)

조립품: 재고자산 증가(데빗)

오버헤드: 지정한 비용/자산 처리 방식에 따라 반영

COGS(매출원가)는 출하/매출 시점에 인식됩니다.

주의 및 권장 사항

음수 수량 허용를 비활성화한 경우, 구성품 가용 수량이 부족하면 제작 확정이 제한됩니다.

로트/시리얼 품목은 개수=수량 일치가 필수이며 중복 시리얼 불가.

BOM 변경·단가 변동 시 빌드 전에 최신화하여 원가 왜곡을 방지하세요.

빈 트래킹 사용 시 From/To Bin을 정확히 지정하여 피킹 오류를 줄이세요.

대량 작업은 작업지시서 또는 작업계획과의 병행 사용을 검토하세요.

관련 기능

Join our Community Forum

Any other questions? Get in touch