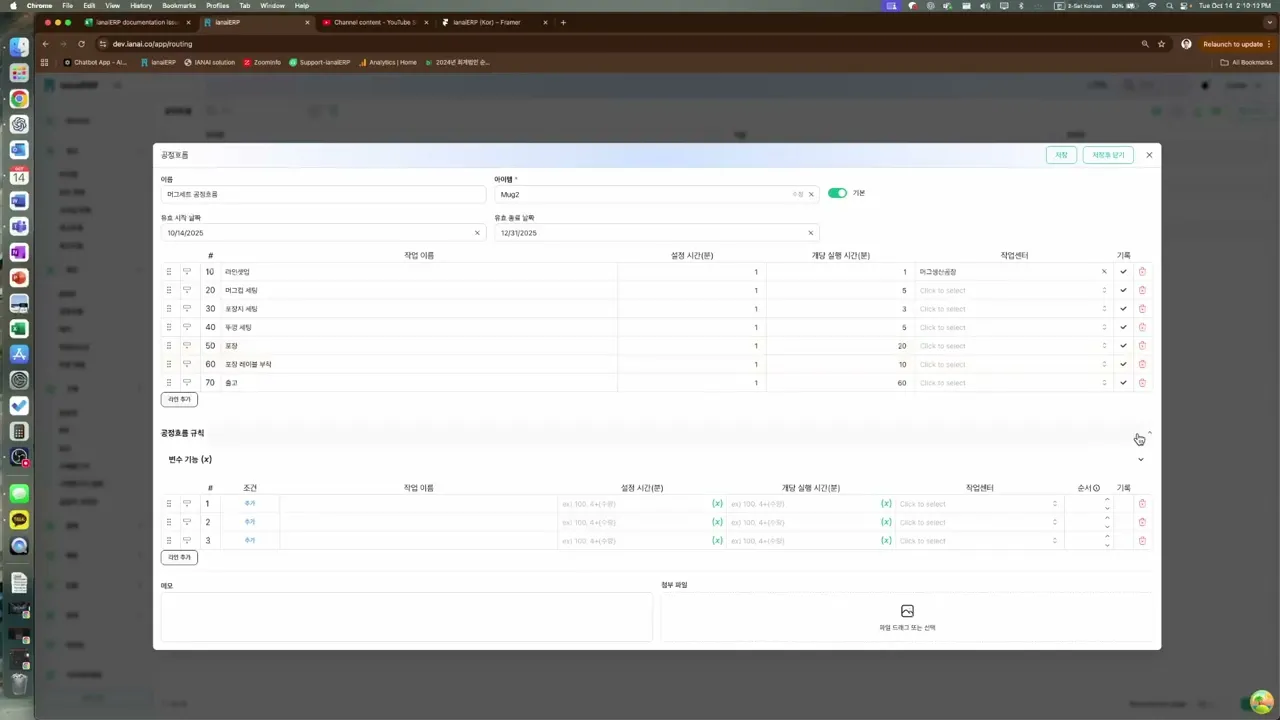

공정흐름

ianaiERP의 공정흐름은 제품 제조에 필요한 작업 순서와 자원을 정의합니다. 작업지시서의 핵심 구성 요소로서, 시작부터 완료까지의 생산 공정 흐름을 명확히 규정합니다.

개요

공정흐름은 원자재를 완제품으로 전환하기 위해 필요한 공정(작업 단계)을 순서대로 정의합니다.

각 공정에는 작업센터, 인력/설비 투입, 준비 시간, 단위당 작업 시간 등의 세부 정보가 포함됩니다.

공정흐름을 올바르게 구성하면 생산 일정, 자원 배분, 원가 계산을 최적화할 수 있습니다.

접근 경로

사용자(관리자/일반)는 좌측 메뉴의 제조 > 공정흐름에서 확인 및 생성합니다.

새 공정흐름을 추가하려면 상단의 “새로 추가” 버튼을 클릭합니다.

주요 속성

헤더

이름: 공정흐름 변형의 내부명(예: “표준–500ml”).

아이템: 이 공정흐름이 적용될 완제품.

기본값(토글): 켜면 새 작업지시서 생성 시 해당 아이템의 기본 공정흐름으로 자동 선택됩니다.

유효 시작/종료일: 사용 가능 기간. 기간 밖에서는 일정계획에서 사용하지 않습니다.

표준 사이클 시간: 단위당 목표 사이클 시간(용량/처리량 계획의 기준치).

공정(작업 단계) 목록

순서(#): 실행 순서(드래그로 재정렬, 관례적으로 10/20/30…).

공정명: 현장에 표시될 단계 이름(예: 절단, 천공, 포장).

준비 시간(분): 배치/런당 1회 투입되는 준비 시간.

작업 시간(분/단위): 단위당 가공 시간(용량/원가에 반영).

작업센터: 해당 공정을 수행하는 설비/셀/자원(설정된 단가가 원가·일정에 반영).

인쇄 템플릿: 단계별로 출력할 작업표/라벨/표준작업지침서가 있을 때 지정.

공정흐름 규칙(조건부 공정)

변수 특성: 아이템 옵션/속성에 따라 공정을 삽입·대체하는 규칙 집합.

조건: 규칙이 적용되기 위한 기준(예: 소재 = 스테인리스).

공정 필드(공정명/준비/작업/작업센터): 조건 충족 시 사용할 값.

배치 순서: 흐름 내 삽입될 순서 번호.

인쇄 템플릿: 조건부 단계 전용 문서 지정.

메모 및 파일

메모: 계획/현장에 공유할 주의사항·특이사항.

첨부파일: 표준작업지침서, 도면, 점검표, QC 문서 등.

주요 기능

공정흐름 생성

제조 > 공정흐름 > 새로 추가.

이름·설명 입력 후 아이템 지정.

공정(작업 단계)을 추가해 흐름을 정의하고 저장합니다.

공정 추가/편집

“공정 추가”에서 공정명, 작업센터, 준비 시간, 단위당 작업 시간을 입력하고 순서를 부여합니다.

단계별 특이사항이나 출력물(작업표/라벨/지침서)이 있으면 인쇄 템플릿을 연결합니다.

작업지시서에 공정흐름 적용

제조 > 작업지시서 > 새로 만들기(또는 기존 문서 열기).

공정흐름을 선택하면 공정 목록이 자동으로 로드됩니다(필요 시 현장에서 값 조정).

공정흐름 규칙 설정(조건부 공정)

제조 > 공정흐름 규칙에서 규칙 추가.

조건(변수/연산자/값)을 정의하고, 충족 시 적용할 공정 정보를 지정.

필요하면 준비·작업 시간을 아이템 속성값 기반으로 산출하도록 변수식을 사용하고 저장합니다.

연관 기능

자세한 공정흐름 최적화 기법과 고급 설정은 관련 문서의 심화 섹션을 참고하세요.

Join our Community Forum

Any other questions? Get in touch